[ad_1]

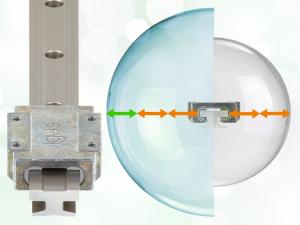

40 percent less friction and a new optimized 3:1 design rule: drylin T Miniature Guide Carriage with new iglide E3 material

STAMFORD, CONNECTICUT, UNITED STATES, July 13, 2022 /EINPresswire.com/ — igus®, the motion plastics specialist, announced it has achieved a breakthrough in tribological plastics. With iglide® E3, igus has developed a new linear material with a friction coefficient of up to 40 percent better than its existing materials. E3 opens up design flexibility in linear technology for its users, replacing the classic 2:1 rule with a newly expanded 3:1 rule.

The igus drylin® T Miniature linear slide offers exceptionally smooth movement and new design freedom thanks to the newly developed iglide E3 material. Depending on the operating point, this has a coefficient of friction of approximately 0.16µ. A miniature drylin T system, using iglide E3, can achieve up to 40 percent less friction than the igus standard materials when measured on hard-anodized aluminum, and even less when compared to commercially available sliding materials. This also means that manual adjustments require up to 40 percent less drive force to move a system.

“This is an important step towards greater design freedom, as it enables us to expand design leeway for the first time,” says Stefan Niermann, head of igus Linear and Drive Technology business unit.

The traditional 2:1 Rule, which generally applies to linear plain bearings, states that the distance between the driving force and the fixed bearing should not be more than twice the bearing leangth. Otherwise, the system could experience chattering, binding or blocked movement. The greater the distance between the drive and the guide bearing, the higher the wear and required drive force. With its E3 material, igus has now extended this design rule to 3:1 so that the drive can be 50 percent further away without impairing linear guide movement. At the same time, the required drive forces are reduced by up to 40 percent, which means 40 percent energy savings in electrically driven applications.

Proven to slide better – without harmful lubricants

The miniature guide carriage with the new iglide E3 liners offers the well-known advantages of igus motion plastics. The solid lubricants incorporated into the high-performing plastic material ensures low-noise operation, high resistance to dirt, and no need for maintenance. Eliminating lubrication is not only cost-saving but also good for the environment. With new material mixing and processing and countless tests in the igus test laboratory, igus has further pushed the application limits of motion plastics and created new design freedom in linear technology.

The drylin T Miniature Guide Carriage is available in three sizes (09mm, 12mm, and 15mm) and can be used in laboratory, medical technology, and many more industries and applications.

To learn more about drylin T Linear Guide Rails and Carriages from igus, click here: https://www.igus.com/drylin/linear-guide-rails

PRESS CONTACT:

Michael Rielly

1.800.521.2747

mrielly@igus.net

www.igus.com

ABOUT IGUS:

igus GmbH develops and produces motion plastics. These self-lubricating, high-performance polymers improve technology and reduce costs wherever things move. In energy supplies, highly flexible cables, plain and linear bearings, and lead screw technology made of tribo-polymers, igus is the worldwide market leader. The family-run company based in Cologne, Germany, is represented in 35 countries and employs 4,900 people across the globe. In 2021, igus generated a turnover of €961 million. Research in the industry’s largest test laboratories constantly yields innovations and more user security. Two hundred thirty-four thousand articles are available from stock, and service life can be calculated online. In recent years, the company has expanded by creating internal startups, for example, ball bearings, robot drives, 3D printing, the RBTX platform for Lean Robotics, and intelligent “smart plastics” for Industry 4.0. Among the most important environmental investments are the “chainge” program – recycling of used e-chains and participating in an enterprise that produces oil from plastic waste.

Michael Rielly

igus®

+1 800-521-2747

email us here

[ad_2]

Source link

The content is by EIN Presswire. Headlines of Today Media is not responsible for the content provided or any links related to this content. Headlines of Today Media is not responsible for the correctness, topicality or the quality of the content.